FLight

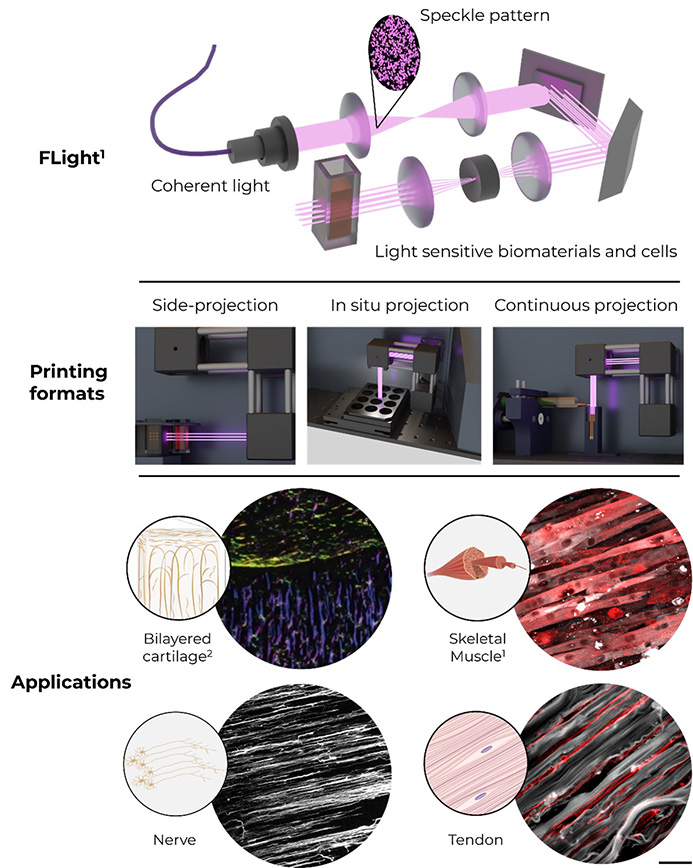

FLight stands for Filamented Light and this is the basis of the biofabrication technology we use to engineer living anisotropic tissues such as tendon, cartilage, nerves and muscle. During FLight printing, a light source with spatial variation in intensity (i.e. speckles, consists of both bright and dark spots) is projected into a container of photosensitive resin. The light induces crosslinking of the resin, leaving behind a permanent record of the light pattern in the form a filamented microgel architecture. The scaffolds can be created directly in cuvettes, vials, and tissue culture plates. Flight scaffolds are composed of highly aligned hydrogel microfilaments with potent cell guiding properties. The confinement of cells and their nuclei by FLight scaffolds is reminiscent of the pore structure found many extracellular matrices of native tissues. We thus have applied FLight biofabrication to applications ranging from cartilage, muscle, nerve and tendons (Figure 1).

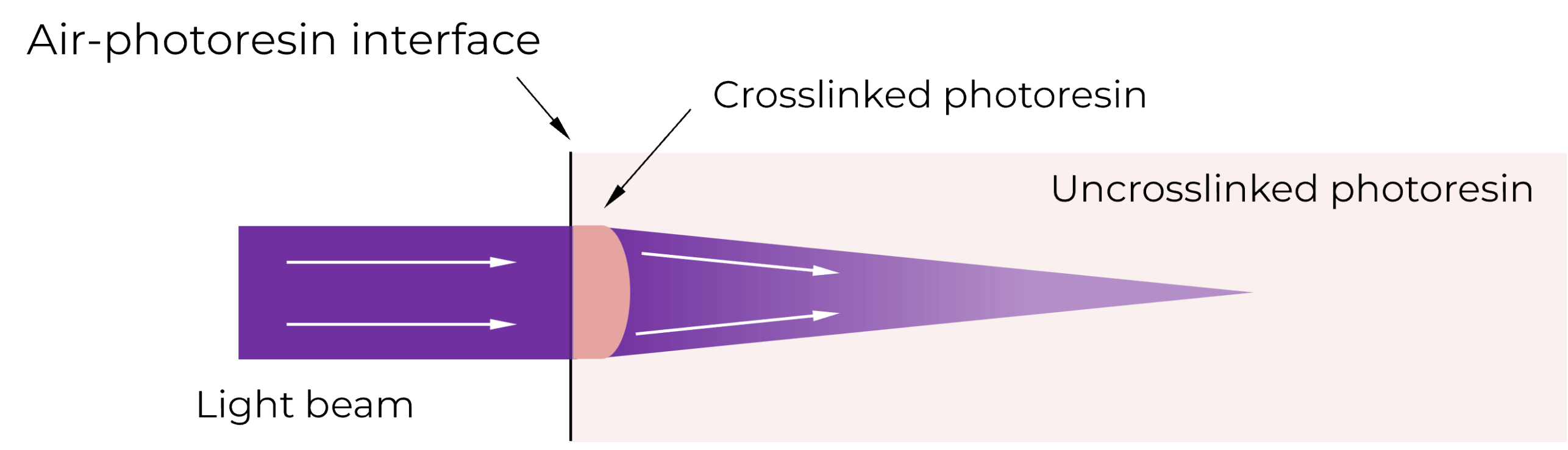

The FLight phenomenon results as local regions at the resin interface which are exposed to bright spots of the speckles which preferentially undergo photocrosslinking. Crosslinking causes a local increase in the refractive index of the material, and the hydrogel acts as a lens to further focus the light (Figure 2). This self-focusing effect further directs the light, resulting in a plurality of hydrogel filaments with extremely high aspect ratio (>1:1000).

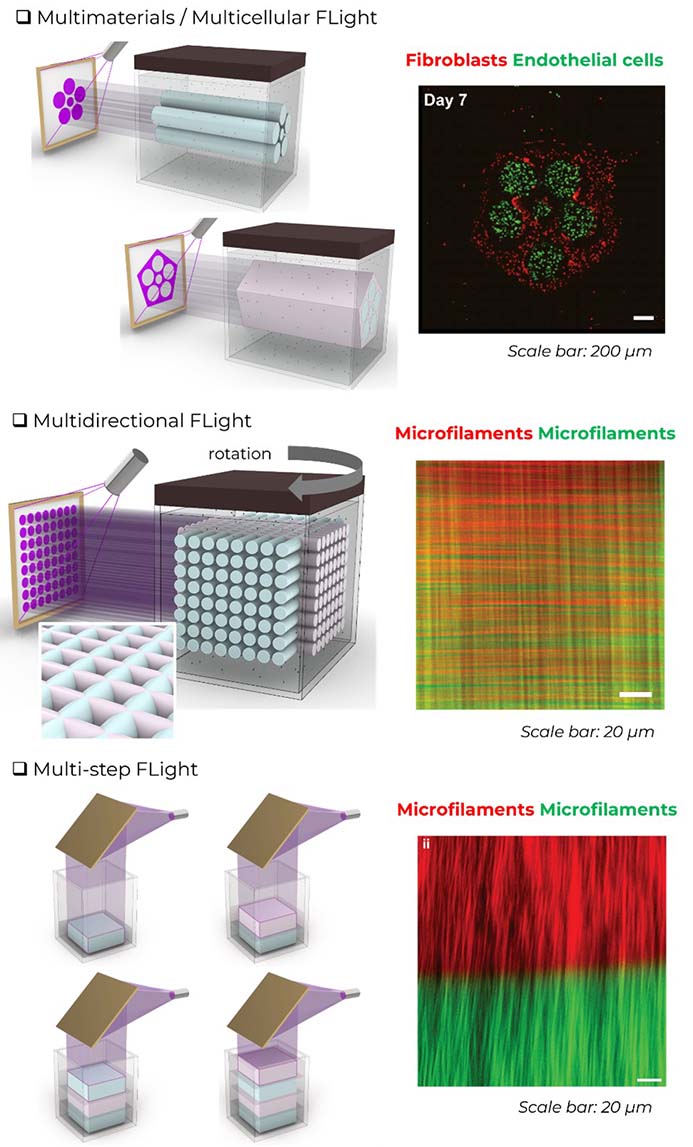

FLight Biofabrication is compatible with multiple materials and the light can be projected in multiple directions, either sequentially or simultaneously (Figure 3). The diameter of the microfilaments and void channels typically range from 3 – 10 microns, with approximately equal volume fractions.

Contact

Gewebetechnol. und Biofabrikation

Otto-Stern-Weg 7

8093

Zürich

Switzerland

Gewebetechnol. und Biofabrikation

Otto-Stern-Weg 7

8093

Zürich

Switzerland